By Benny Evangelista

San Francisco Chronicle

WWR Article Summary (tl;dr) Although 3-D printers and milling machines work differently, they represent the same basic philosophy that entrepreneur Bre Pettis and others in the maker movement espouse: giving everyone tools to be creative.

San Francisco Chronicle

Entrepreneur Bre Pettis sparked an unfinished revolution in 3-D printing.

Now he has purchased a Berkeley company that wants to make the manufacturing of everything from fine jewelry to precision electronic parts just as accessible to the masses as desktop publishing.

Last month, Pettis bought Other Machine Co., which makes a portable milling machine for electrical and mechanical design engineers and educators who want to quickly create prototypes.

Other Machine co-founder and CEO Danielle Applestone believes her company’s machine could represent a future of manufacturing — reliant more on the innovation of individuals and less on giant factories.

“If the means of production are inexpensive and easy enough for anyone to use, more people will produce things,” she said.

“We’ll have a lot of really small factories,” she said.

buy professional pack generic buy professional pack online no prescription

“I see that as more economically robust, because you don’t have to bail them out. If one fails, then another one starts and it’s not that big of a deal. But that hasn’t happened, mostly because the tools are so expensive and you had to be trained on them.”

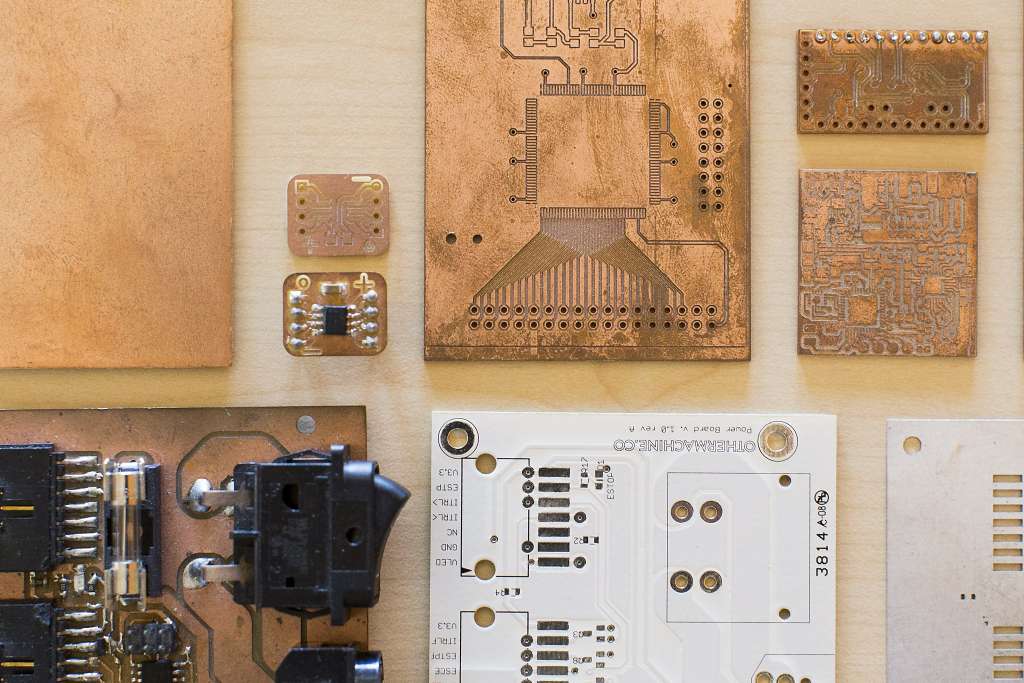

The company’s product, the $3,199 Othermill Pro, is a 17-pound, computer numerical controlled milling machine capable of creating parts out of a variety of materials. Unlike a 3-D printer, which adds layers of material to create a product, this machine subtracts parts of the material.

To demonstrate the Othermill Pro, which is less than 1-foot square, an Other Machine worker programmed the computer-controlled blade to etch lines one-6,000th of an inch thick on the surface of a small copper-clad surface that could become part of a computer board.

A Twitter member named QCPete tweeted a photo this week of a circuit board he made with the Othermill. “I only finished the design 2 hours ago, and now it’s in my hands. Totally awesome!” he wrote.

Pettis, a Brooklyn entrepreneur who sold 3-D printing company MakerBot in 2013 for $404 million, bought Other Machine for an undisclosed amount. Applestone remains CEO, and Pettis plans to advise the company.

Although 3-D printers and milling machines work differently, they represent the same basic philosophy that Pettis and others in the maker movement espouse: giving everyone tools to be creative.

“My life is dedicated to empowering people to be more creative and to reach their full potential,” Pettis said.

The hype around MakerBot didn’t result in 3-D printers on every consumer’s desktop, as Pettis and other proponents once promised, said Gartner research analyst Pete Basiliere.

But he said 3-D printing is affecting manufacturing in “virtually every industry,” and products such as Invisalign dental braces and hearing aid cases are now made with that process.

Applestone said she knew Pettis from their maker community connections, and had sought his advice on how to expand Other Machine, which began in San Francisco in 2012 with a Defense Advanced Research Projects Agency grant. The company moved to its current 5,000-square-foot space in March 2016.

Applestone doesn’t expect the Othermill to be a consumer-oriented product, but she hopes it will inspire creativity in a new generation of engineers and designers.

“If you put those kinds of tools in the hands of people, you’ll have way more people who are innovating much quicker than larger companies can,” she said.