By Lydia DePillis

Houston Chronicle

WWR Article Summary (tl;dr) “TX/RX” — which stands for “transmit/receive” is emerging as a center for Houston startups, small manufacturers and people who just want to make stuff.

Houston Chronicle

A few years ago, a researcher at the Texas Medical Center was ready to use a multi-million-dollar machine for imaging rat brains — except she needed it for mice, whose heads were too small for the machine’s holes. Spray foam and duct tape didn’t fix the problem.

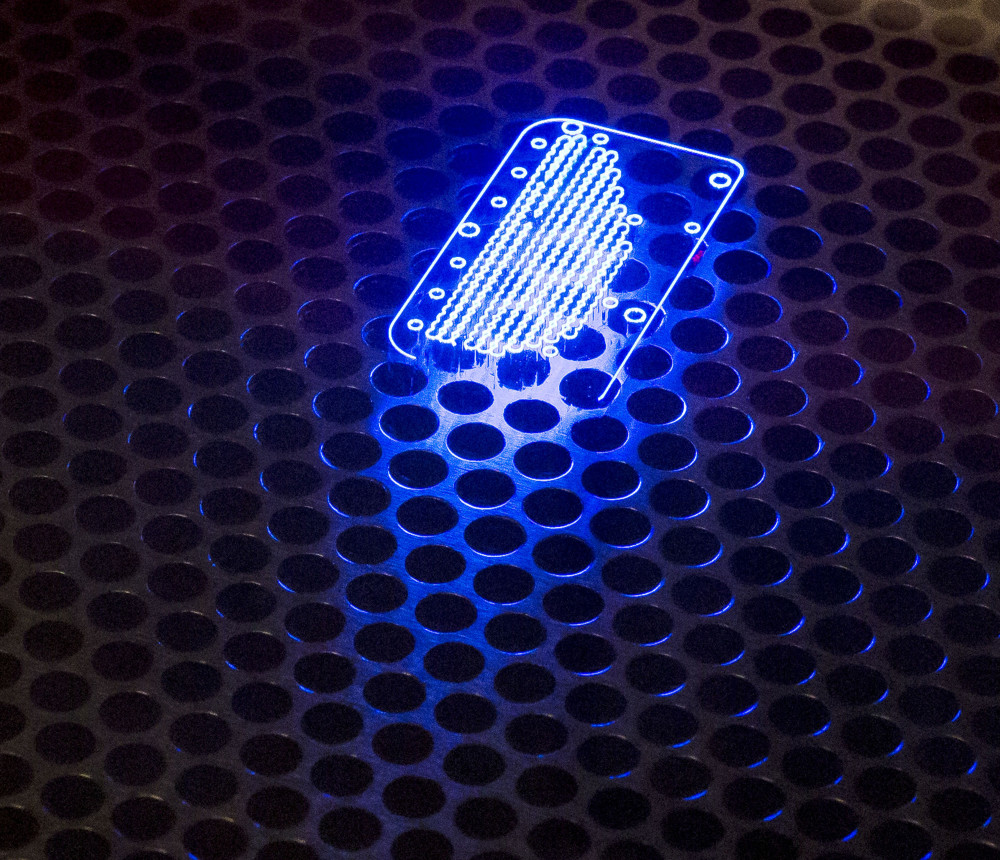

Near desperation, the researcher found Ronald von Kurnatowski III, who runs a nonprofit fabrication workshop in Houston’s East End called TX/RX Labs. His staff used a 3D printer to forge inserts sized for mouse heads. Crisis averted.

“That’s not a complex problem to solve,” said von Kurnatowski, a tall, garrulous former application developer for JP Morgan who now comes to work in grease-stained pants and boots. “The problem is, they have a bunch of medical researchers, and they’re trying to task them with a set of problems that are meant for mechanical, electrical, and material engineers.”

TX/RX — which stands for “transmit/receive” — has quietly supplied solutions such as mouse-head inserts to medical researchers and other innovators for eight years, emerging as a center for startups, small manufacturers and people who just want to make stuff.

As the city forges a strategy to Houston’s tech scene with tax incentives and an “innovation district,” Kurnatowski wants to make sure that entrepreneurs and engineers who specialize in hardware are not forgotten in the hype around software and mobile apps.

That’s especially important now, when TX/RX, having outgrown its 55,000-square-foot space, is planning the next phase of its development.

Underway is an expansion into a much larger building, where Kurnatowski hopes to ramp up both educational activities and the ability to house more small companies.

To finance the project, he needs a low-cost loan from the federal government — and for that, he needs a hand from the city as well.

Making a movement

In recent years, the popularity of tech startups as an economic development tool and a cultural phenomenon — typified by the image of a teenage hacker spinning out lines of code in a college dorm room — has grown in parallel with a smaller, but no less passionate movement around building stuff that’s more tangible.

Adherents of this movement call themselves “makers,” building everything from wood furniture to complex electronics. In Houston, the movement got underway when a group of makers started meeting in a coffee shop in midtown in 2009 to show off projects and swap feedback.

They soon decided they needed a dedicated home, and after a brief stint at a small temporary space, rented a warehouse on Commerce Street, filling it with secondhand equipment like lathes and CNC machines purchased at auction from manufacturing companies.

Fueled at first just by donations, they later brought on paid staff who teach classes in jewelry-making, welding, ceramics, computer-assisted design, and other subjects. Year by year, TX/RX grew into a complex of four adjacent buildings, adding separate workshops for different crafts as well as studio space for rent.

These days, it’s become one of the only places in Houston with the equipment and expertise to host advanced courses for other educational institutions,such as a summer residency program through the American Institute of Architects, and foundry and design classes for the Museum of Fine Arts’ Glassell School.

It’s also one of the only places for small companies with novel inventions to find affordable space with access to machines and the kind of collaborative atmosphere that fuels creativity.

Alexander Wesley, for example, invented a foldable fabric display that projects a screen from your laptop or smartphone — called the Spontaneous Pop-Up Display, or SPUD — while in business school at Rice. Owlspark, Rice’s business accelerator, initially paid for his TX/RX membership as he prototyped and refined the product using 3D printing machines, welding and woodworking equipment. After graduating, his company, Arovia, became a full-time tenant.

“There were no other options,” Wesley said. “We make a physical product.”

His company, which now employs four, has raised $700,000 on Kickstarter to start producing SPUDs.

Another type of company that lives at TX/RX focuses not on its own signature product, but rather solving problems for others. Mark Sullivan runs Cyclotronics, which takes on custom engineering projects, from a device for the U.S. Fish and Wildlife Service that catches prairie chickens to internet-connected window blinds and oil drilling devices.

Good jobs at good wages

Cyclotronics, which has eight employees, operates out of a few windowless rooms in one of TX/RX’s four warehouses, and takes orders from anyone who comes across a challenge they don’t have an engineering staff to bring their products from design to delivery. “The biggest thing that happens to people is they have an idea and they don’t know what to do next,” Sullivan said.

TX/RX’s backers say that helping inventors get from idea to product and solving other technical problems could be a source of well-paid jobs for creative people with a wide range of skills. To help local young people access those careers, TX/RX works with nearby high schools to offer classes in several kinds of fabrication, free of charge.

Angela Pitcher teaches at the Energy Institute High School, an energy-focused public school that teaches by assigning collaborative projects, rather than testing kids to make sure they know something. She said her students adored the after-school program — progressing from name tags cut with lasers to their own lamps, designed on a computer and cast out of aluminum.

“I had kids who wouldn’t turn in an assignment for me, but they wouldn’t miss an after school class at TX/RX,” Pitcher said. “When the students make something with their hands, the whole mood changes, learning changes.”

That’s not just good for the kids — it’s potentially the future of the historically industrial East End, which has plenty of empty and underused industrial buildings. The Greater East End Management District, a quasi-public agency responsible for improving and beautifying the neighborhood, sees TX/RX as a bridge to less polluting, higher-value manufacturing.

“What you have now is a lot of innovative, highly technical smaller manufacturing firms that are producing high end products,” said Patrick Ezzell, the group’s head of economic development and infrastructure. “It’s a good match, because it helps to build wealth in the community.”

Breaking the mold

As TX/RX’s activities continue to expand, adding more classes and more members and tenants, the innovation environment in Houston may be about to change substantially.

The city and the business community have made recommendations on how to boost Houston’s capacity for innovation and venture capital funding for small tech companies. So far, city and business leaders have focused largely on information technology firms with potential to file intial public offerings or get bought by a larger company.

Von Kurnatowski worries that in the rush to embrace Silicon Valley-style entrepreneurship, the opportunity to support smaller-scale hardware startups that serve Houston’s biggest industries might be lost. He knows that inventing devices and bringing them to market is complex and challenging.

“It’s a harder model than ‘Hey let’s make it a cloud-based, scalable service and sell it for $40 billion,'” von Kurnatowski said. “But not everybody’s going to do that. People need physical products.”

So far, TX/RX has grown organically, with only small grants from companies like Cognizant and WeWork to supplement its income. Classes cost about $50 per session, and memberships run from $50 per month for limited access to tools to $800 for a full studio lease. Revenue reached $456,000 in 2015, according to the most recently available tax returns. Kurnatowski and most of his leadership team are volunteers, with 11 paid staff.

But an expansion of the size he’s contemplating might require some more assistance. The city’s Office of Economic Development invited TX/RX to apply for a low-interest loan guarantee program for developments that help low-income people or eliminate blight.

Von Kurnatowski estimates that it would cost between $10 million and $35 million to retrofit the new space. Lining up the capital and the support necessary to pull it off might be tricky, he admitted. It’s hard to sell grant-makers and financial institutions on a concept that hasn’t been seen before in Houston, that isn’t a traditional job-training program or business incubator.

“We built this place the way we did to get people to see one thing: Getting people to design build and learn without necessarily clear outcomes has value,” von Kurnatowski said. “If you want to make people makers, you can’t box it in with some pre-set formula.”