By Shanon Quinn

Moscow-Pullman Daily News, Moscow, Idaho.

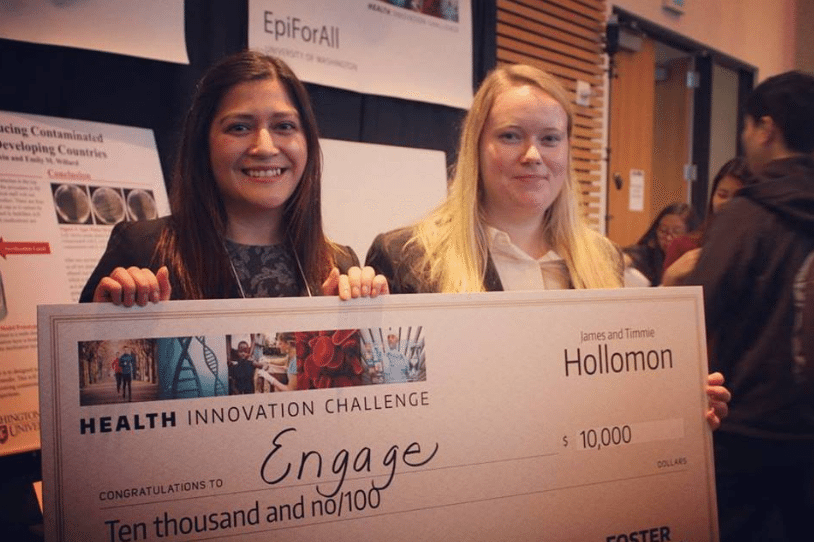

WWR Article Summary (tl;dr) Two Washington State undergrads created a medicine vial cap that sterilizes needles with every use. The 21-year-old bioengineering majors were working on a class project that would hold their interest and also have a social impact. Now after winning $10,000 in a Health Innovation Competition they will be exploring what is next for the cap as well as their future as women in business as the founders of their new company named “ENGAGE” for Engineering Accessible Global Equipment.

Moscow-Pullman Daily News

What began as a class project for two Washington State University seniors is now looking like the beginning of promising careers — with a dose of world-changing innovation thrown in for good measure.

Katherine Brandenstein and Emily Willard’s creation, a medicine vial cap that sterilizes needles with every use, was the winner of the University of Washington’s Health Innovation Challenge on March 3.

Brandenstein and Willard, both 21-year-old bioengineering majors, were in their senior capstone class for about four weeks when they joined together to create a project that would hold their interest and also have a social impact.

“We Googled problems in developing countries and this was one of that popped up — the contamination of medicine,” Brandenstein said.

Due to the chronic reuse of needles, nearly half of the injections given annually in these countries are done with contaminated medical equipment, resulting in the spread of blood-borne pathogens like HIV and hepatitis — major causes of death in developing nations.

“Their big problem is there’s contaminate on the needle and the second it touches the medication all of that medication is contaminated,” Brandenstein said. “Most of these are 10-dose vials, so the rest of the people getting medication from it are all getting contaminated.”

The cap the women developed — and brought to life on a 3-D printer — could change all that.

“There’s a hollow shell on the inside of it and it’s filled with a sterilization liquid,” Brandenstein said. “There’s needle rubber put onto both sides of it on top of a normal multi dose vial.”

Willard said one of the benefits of the invention is its very simplicity.

“You don’t have to build this complicated machine and teach health care workers how to use it,” Willard said. “They just fill a syringe like they normally do.”

The women said the cap makes safe injections foolproof and unavoidable.

“Trying to get it off is extremely hard. We wanted it to be something that could be integrated really easily and we wanted it to be cheap. It just gives an extra layer with a sanitization liquid that forces the needle to go through it before it ever touched the medicine, that way there is no contaminate on the needle,” Brandenstein said.

The sterilization liquid the women are currently using is ethanol, as studies show it inactivates HIV and hepatitis.

Brandenstein said she and Willard entered the UW competition after they heard the winners would bring home $10,000 to develop their prototype, but didn’t anticipate going as far as they did.

“I don’t think initially either one of us thought we would end up in the finals or winning it,” she said. “And we were the only non-UW team there. We were really excited to be there representing our school.”

As their undergraduate career at WSU draws to a close, the women have no intention of closing the doors their idea has opened.

They will be attending meetings over the remainder of the year and throughout the summer to discover the feasibility of broad-scale use of the cap as well as the future of the company they have named ENGAGE for Engineering Accessible Global Equipment.