By Ted Griggs

The Advocate, Baton Rouge, La.

WWR Article Summary (tl;dr) Several facilities in Louisiana are now offering entrepreneurs the equipment needed to explore the world of 3-d manufacturing. Several local “makerspaces” now offer the use of 3-D printers, laser cutters, and other advanced manufacturing appliances.

The Advocate, Baton Rouge, La.

A few years ago, Bioceptive Inc. needed a 3-D printer to mock up parts for its new intrauterine device inserter, which relies on suction rather than the pinch and pain of forceps. The startup had to go out of state.

Bioceptive was locked into a time-consuming and expensive cycle. The company sent its designs to national prototyping houses, waited a couple of weeks for the part to come back, tested it, tweaked the design and repeated the process.

“It was a pain in the butt,” said Aaron Miscenich, president of New Orleans BioInnovation Center Inc., the tech incubator where Bioceptive is a tenant.

Luckily, the University of New Orleans had a 3-D printer in the Naval Architecture and Marine Engineering Department, and Miscenich had a brother who graduated from the program and knew about it.

Bioceptive CEO Benjamin D. Cappiello said the company also was fortunate that Associate Professor Brandon Taravella was making the device available to local businesses.

“Now our iteration cycles were days instead of weeks, which makes a huge difference,” Cappiello said. “Something that would have cost $400 before was maybe costing $30 or $40.”

Just as importantly, Bioceptive got its parts back the next day, he said. On one specific piece, Bioceptive went through 55 different iterations. Access to the local 3-D printer probably saved Bioceptive tens of thousands of dollars and cut development time by years.

Bioceptive has since moved past the need for 3-D printing. A reusable version of its device is now in clinical trials. But entrepreneurs no longer have to go out of state for their prototyping needs. Some of the other options available include:

–IDIYA on South Broad Street, which CEO Dominic Guinta described as a “do-it-yourself design, prototyping, and build shop.”

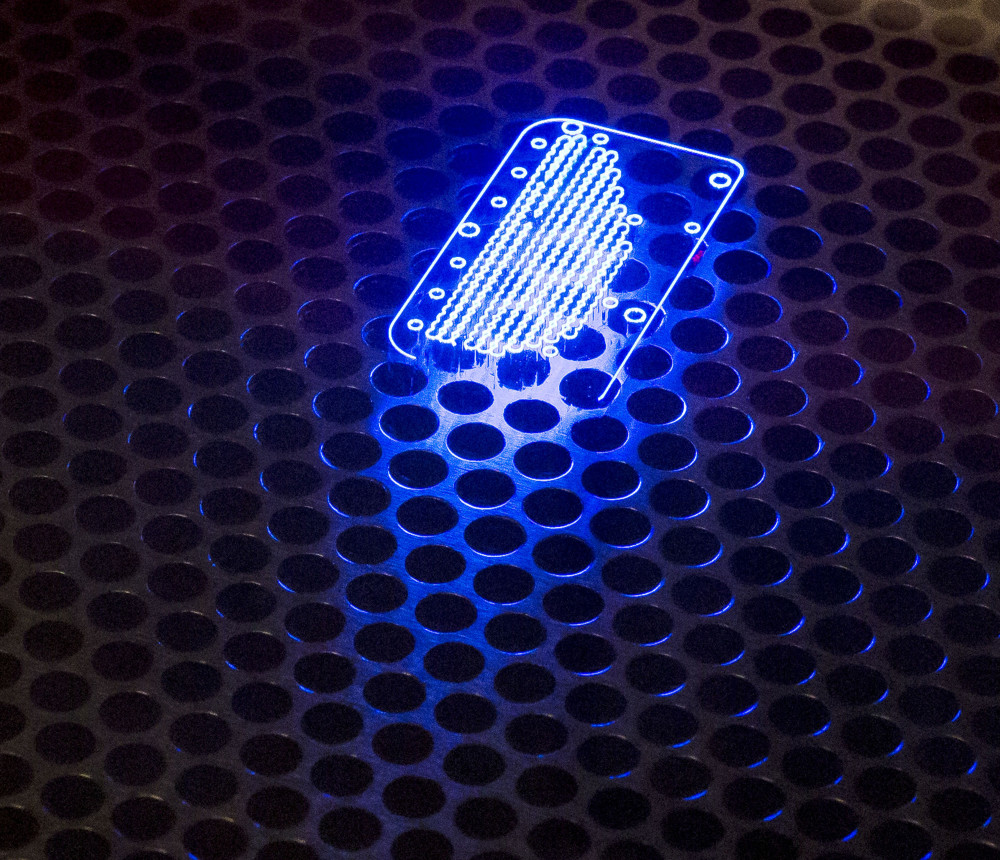

The facility has more than 10 3-D printers, some of which can print in carbon fiber, three laser cutters, two computer numerical controlled milling machines, and other advanced manufacturing equipment.

The facility is open to the public for a membership fee. The price depends on the membership plan. IDIYA also offers members classes and connections to others in the creative community. IDIYA’s vision, according to its website, is to put manufacturing back into the hands of individuals.

–ProtoStripes Center at LSU’s Louisiana Business and Technology Center. The center is open to anyone in Louisiana and recently added a 3-D printer, laser cutter and computer numerically controlled milling machine. The new equipment allows ProtoStripes to create more intricate designs with higher tolerances.

buy viagra super dulox force online pridedentaloffice.com/wp-content/themes/twentytwentyone/inc/en/viagra-super-dulox-force.html no prescription

–The Maker Space at Tulane University. Tulane’s Maker Space wiki describes makerspaces as “a new amalgam of art, craft and technology.” The facility is restricted to Tulane faculty, staff and students, but there is no limit on what a person can make.

Tulane spent more than $900,000 to renovate the 4,100-square-foot facility built in 1894, and about $100,000 on new equipment. The Maker Space also inherited about $400,000 worth of equipment along with the facility, a former machine shop.

“What has been most interesting to me is the number of people from the arts and social sciences who come over to make use of it,” said chief maker Cedric Walker. “One of the very first clients we had was a woman who was working on her master of fine arts degree, and she wanted to make porcelain lace.”

The Maker Space used a laser cutter to make a flat, plywood mold. When the artist fired the kiln, the mold burned away leaving just the porcelain lace, Walker said. Last Halloween, a raft of students used a temporary version of the Maker Space to make ultrasonically activated robotic Silly String shooters.

Lee Wellington, executive director of the Urban Manufacturing Alliance, said investments in these types of facilities are part of a growing trend at high schools, and two- and four-year colleges.

For example, Mildred Osborne Charter School in New Orleans recently launched a new “makerspace” with a $126,100 grant from Capital One Bank, Propeller, an incubator that targets New Orleans-area entrepreneurs, and IDIYA.

LSU’s business incubator, the Louisiana and Business Technology Center, established the ProtoStripes Center in 2014. The center has worked with 42 entrepreneurs on 104 prototypes.

“I think the one thing that we’re noticing is that you don’t just see investments in 3-D printers. We’re also seeing investments in the kinds of programs that are helping students understand how to take products to market,” Wellington said.

Students learn how to fabricate a product using 3-D printers and how to build a business model to manufacture it, she said.

Thomas Wavering, executive director of the University of Oklahoma’s newly established Innovation Hub, said the idea behind these sorts of facilities is not just having a cool makerspace and tools for people to play with.

“What we’re trying to say is ‘OK, how does a place like Norman, Oklahoma, or Baton Rouge or wherever, how does that become more like Silicon Valley or Boston or Austin in terms of kind of an entrepreneurial ecosystem?'” he said.

Oklahoma created the Innovation Hub as a first step. The hub is a space where people from across the university and community, the technical and nontechnical, can connect and collaborate to support invention and entrepreneurship.

Walker said the Maker Space tries to lower all the barriers. There’s no charge for materials, such as plywood or the filament for the 3-D printers, or to use the equipment.

“Frankly, bringing people in saying, ‘Sure, go ahead and use it,’ sort of hooks them to come in and try new, creative ideas,” Walker said.