By Frederick Melo

Pioneer Press, St. Paul, Minn.

WWR Article Summary (tl;dr) Volunteers are doing everything they can to make sure front line workers have all of the equiptment they need to protect themselves while treating patients.

St. Paul

Regina Kieti arrived in the basement of Allina Health’s headquarters on Minneapolis’ Lake Street at Thursday morning, the beginning of an eight-hour shift stapling and gluing plastic covers to soft foam head pieces.

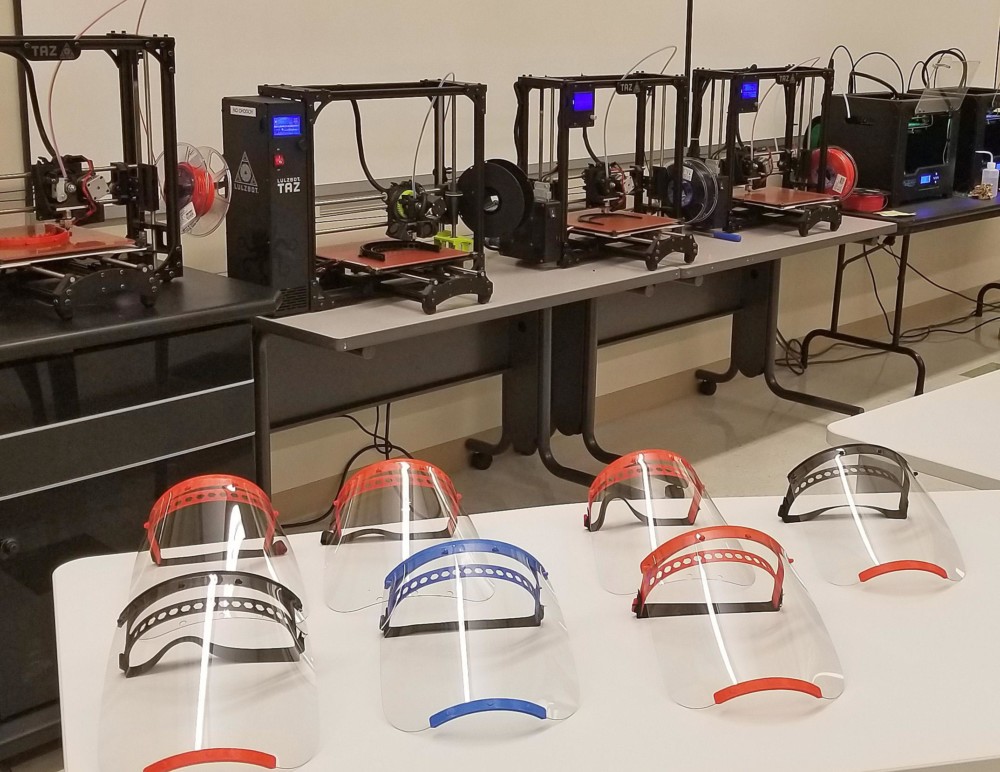

Kieti, a licensed practical nurse with a breast cancer center in Plymouth, planned to return the next day to continue her efforts. The goal: 10,000 facial shields for nurses and other front-line workers who will soon be tending to Covid-19 patients throughout the Allina Health system.

On an upper floor of the Allina Commons building, top-level administrators have created an “incident command” structure, sending out directives to 10 Allina hospitals and 90 clinics throughout the state while fielding questions and concerns in response.

In the basement of Allina Commons, volunteers from the health network’s clinical and corporate offices converged for a simpler mission, many meeting for the first time in a common cause: to get ahead of a patient surge.

“We cannot send our front-line workers into war without armor,” said Kieti, who moved to the U.S. from Kenya on Sept. 11, 2001. “It’s a war. And that’s how we fight it.”

Kieti and dozens of other Allina workers answered a request for volunteers that went out Tuesday afternoon. By Wednesday, 166 spots had been filled, about double the needed manpower.

But Maggie Sartori, a supply chain director for Allina Health, said it may only be 10 days before the remaining volunteers are put to work assembling more face shields as soon as the next shipment of materials comes in.

“They’re very simple — they’re composed of just a couple plastic parts,” said financial analyst Cathy Strommer, an Allina worker for more than 30 years.

Nevertheless, nurses hope the simple shields and other “PPE” — or personal protective equipment — will make a difference in keeping front-line healthcare workers from becoming infected as they tend to the very ill.

Given virus-related disruptions in China, where many American healthcare products are manufactured, even the simplest PPE has been in short supply around the country for those who will likely need it most.

Internet retailer Amazon is shipping face shields from a manufacturer in Maryland that has a back order of about three weeks, Sartori said.

So she relied instead on volunteers to assemble their own using an instructional design issued by Johns Hopkins University, modified in part by materials supplier Woodchuck USA, a manufacturer based in northeast Minneapolis.

“They got it all together for us. They actually simplified the process,” Sartori said. For the foam pieces, “they have adhesive tape instead of hot glue guns.”

At the West Health breast center in Plymouth, Kieti and her co-workers greeted the last of their traditional patients on Monday. They showed up Tuesday ready to be activated if coronavirus patients arrived. “We were at our stations, just ready, set and go! Whatever needs to be done.”

For the past year, whenever she’s hit a wall while handling X-ray software, Kieti relied on Sherry Jenkins, the PAX systems administrator and faceless “savior” on the other end of her online help requests. On Thursday, the two women met face-to-face for the first time while working together at one end of a long table converted into an assembly line of sorts for shield production.

“She’s my savior,” Kieti said. “Whenever I’m in a crisis, she’s the one that fixes everything.”

By the end of the day, some 80 volunteers had filled dozens of bags with face shields ready to distribute throughout the Allina system.

___

Distributed by Tribune Content Agency, LLC.